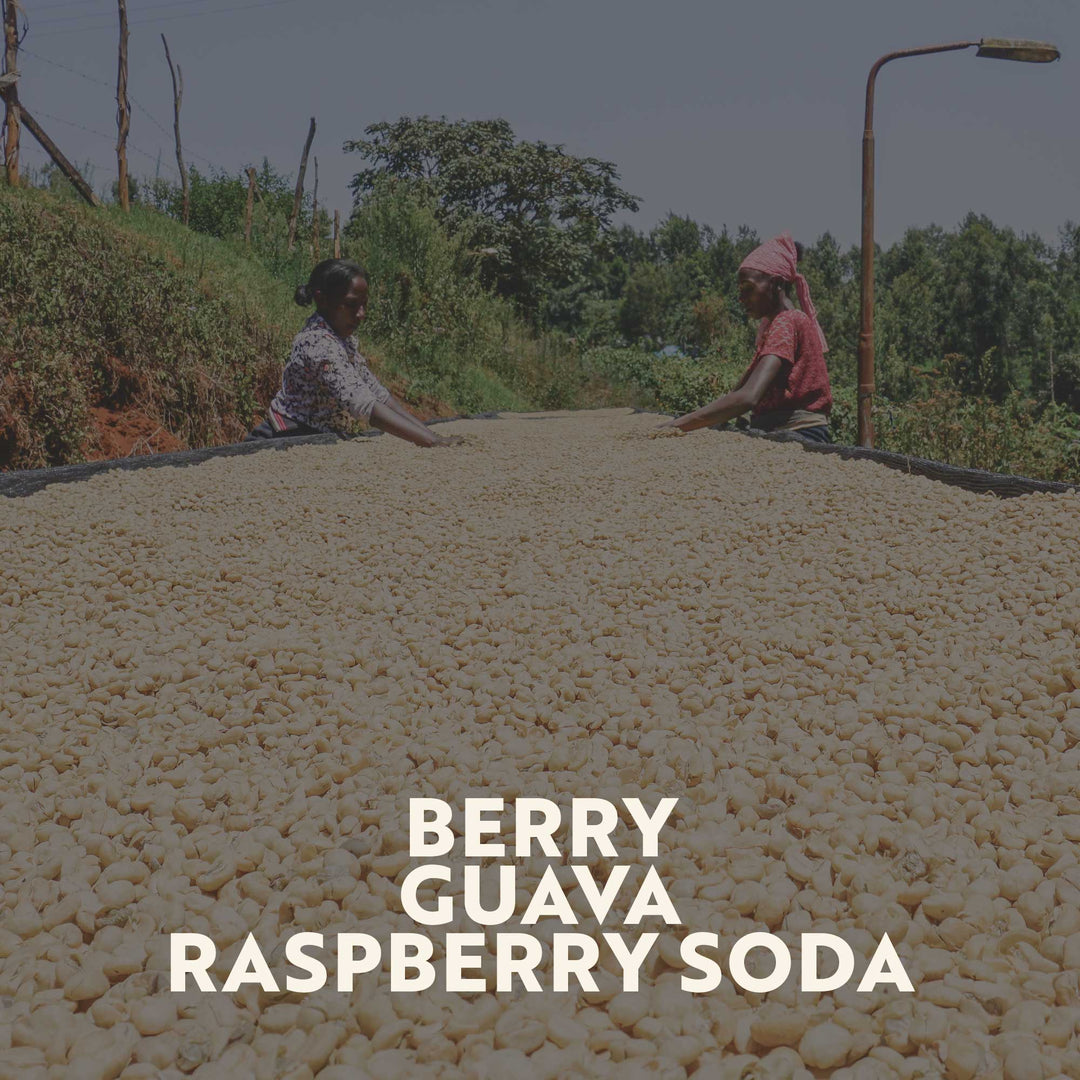

Kenya - Kirinyaga (Filter Roast)

- Roasting Fresh Daily

- Free Shipping over $70

| Origin | Njukiini in Gichugu Division, Kirinyaga County |

|---|---|

| Flavour | A juicy cup with notes of black tea, red berries, guava and a sparkling soda sweetness. Gentle floral notes lingering. |

| Varietal | SL28 SL34 RUIRU 11 |

| Acidity | Medium |

| Body | Tea Like |

| Roast | Light |

| Brewing | Roasted for specifically for Filter. V60, Aeropress, Frenchpress etc |

Roasters Thoughts: "Kenyan coffees are just a joy to work with. Such an elegant and easy drinking coffee, super delightful and it's seriously just ticking all the boxes, which is what you want from a high end filter brew. You really can't go wrong with this."

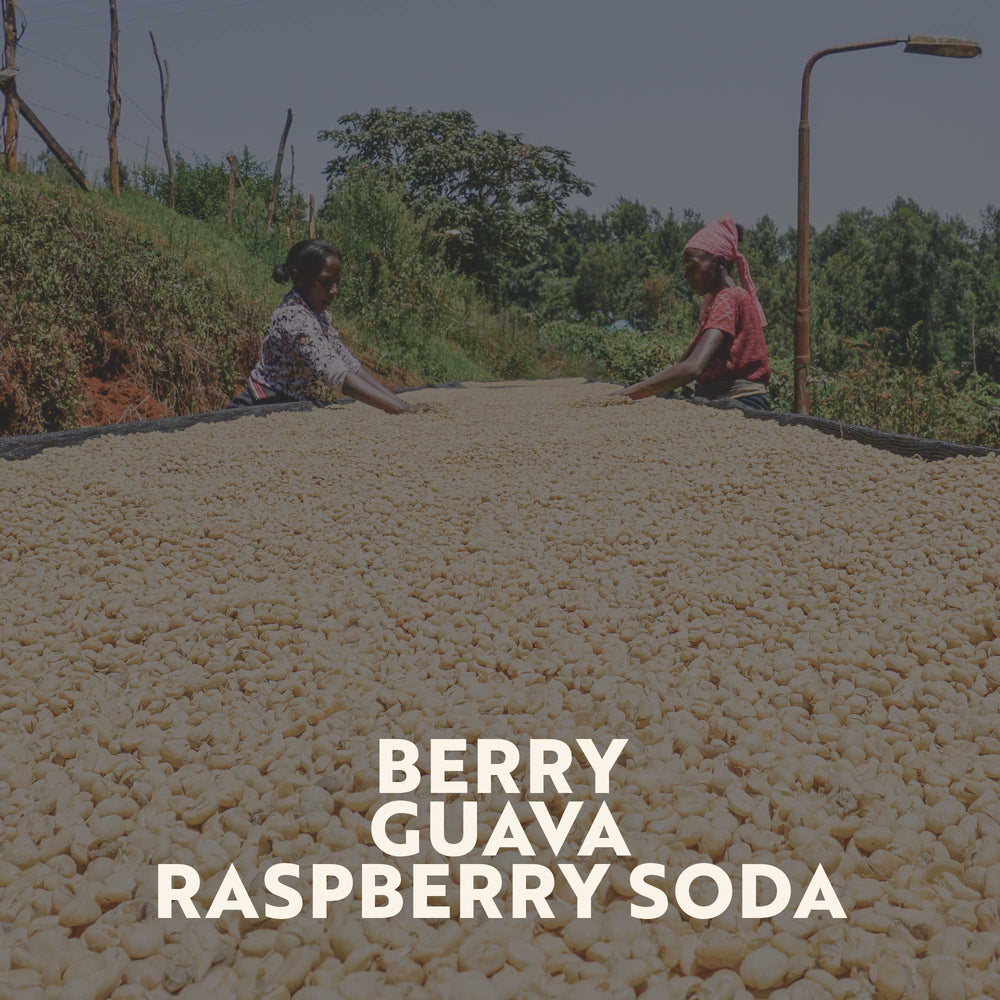

Kiri Factory is located in Njukiini in Gichugu Division, Kirinyaga County. Njukiini is a local name meaning the place of bees. The Kiri factory has around 1400 members delivering cherry to be processed. The factory was established in 1997 to serve 4 zones that did not have access to processing, has 20 full time staff members and typically around 30 casuals during the peak times.

Soil Type - The farm benefits from deep red volcanic soils, rich in organic matter.

Rainfall - Approx 1300-1500 mm per annum.

Processing Method - The ripening of the cherry is closely monitored and when the time is right the red cherry is hand picked into buckets early in the morning and carried to the wet mill. The harvested cherries are splayed out on a patio at the wet mill in the afternoon light, with underipes, overipes and any foreign object being removed before the mass of round red cherries are tipped into the hopper above the pulping station. Clean water (wet processing) from their dam which is fed from River Chania is drawn up and poured into the hopper on top of the heaped cherries, funnelling them down through a polished chute into the pulping house where the outer fruit is removed between two rotating abrasive slabs.

As the now exposed coffee beans tumble out of the pulper into a channel of water, the floating beans are skimmed off, and the sinking denser beans pass out through a hole in the bottom spilling into the fermentation tanks were they spend the night. The next day the coffee is handled to see if the sticky sweet mucilage has broken down, leaving a rough parchment coating, once "the feel" of the coffee meets the wet mill manager's approval, water will be poured into the tanks to thoroughly wash the beans.

Once washed, the sluice gates are lifted allowing the coffee to spill out into the washing channels, in here the coffee slides down the gently sloping tiled channel. Wooden shunts are used to repeatedly push the coffee by hand back to the top of the channel, this repeated action separates the denser beans as the lighter beans will race back to the bottom under the force of the gentle current, whilst the denser higher quality beans will idle there way slowly down.

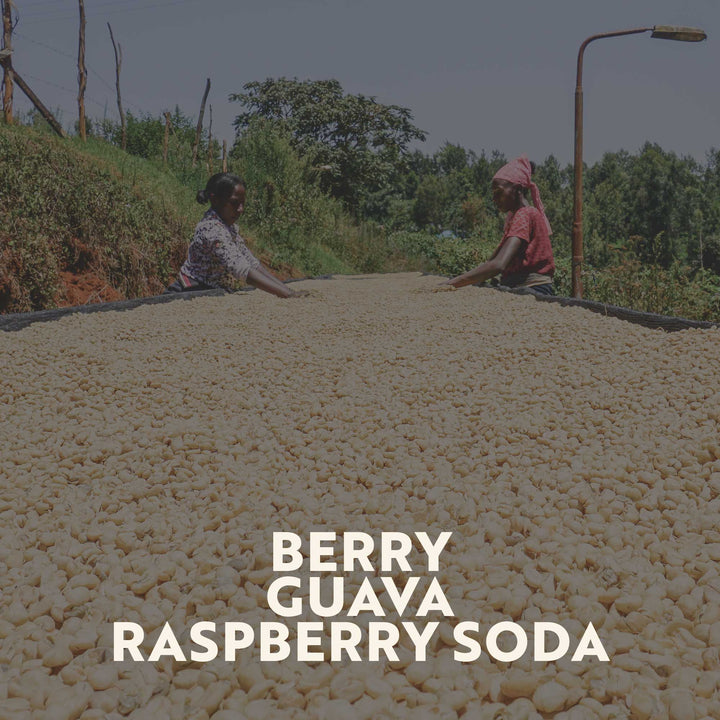

Sun drying of the parchment coffee on raised tables is done under careful supervision, the parchment coffee is covered up whenever there is sign of rain or the sun's rays are too harsh. The coffee is regularly checked for moisture and once it reaches the 10-12% target level, it will be bagged up for transport to the dry mill.

Our Flat Rate $10 shipping options will default to either Couriers or AusPost depending on relevant shipping ETA's, if you require fast or urgent shipping please upgrade to the Express Option for $15.

All qualified Free Shipping purchases will be treated with the same protocols as the Flat Rate option.

We try our best to dispatch within 48 hours of purchase. Excluding weekends.